This data migration project at Miller encountered a few specific challenges since data had to be converted from an existing multi-site environment (multi-logistic/multi-finance) in Baan IV_c4 to a multi-site environment (multi-logistic/multi-finance) in ERP LN.

In order to perform these complex tasks, Miller Industries selected Migration Labs as the data migration specialist who understood Miller’s specific needs and was able to solve the special migration challenges.

During the data migration, conversions had to take place for back orders in Sales Order Management, lot numbers in Baan IV to serial numbers in ERP LN, and all open entries related to existing master data.

All open sales orders in Baan IV had to be migrated as back orders in ERP LN. Since several organizational procedures were associated with the back orders, Miller needed flexibility in the migration solution to change the data converted from Baan IV to ERP LN accordingly.

At the same time, Miller required another data-reorganization so that lot data in Baan IV could easily be converted to serial data in ERP LN, as this is able to handle serial numbers. Many companies using Baan IV today are just like Miller and utilize the lot functionality since no separate serial numbers have been available in Baan IV. In order to use this enhanced functionality in ERP LN, no 1:1 migration was acceptable for Miller. Migration Labs provided a solution to easily convert the lot-related data into serial data.

According to Sias Reyneke, IT Director at Miller Industries, the easybaan® Toolkit and methodology was selected as the only solution able to handle all of the complexities of migrating data from Baan IVc4 to Infor ERP LN™.

According to Sias Reyneke, easybaan®’s unique framework allowed Miller Industries to migrate Baan IV data in a multi-site (multi-logistic / multi-finance) environment and accomplish a partial migration of the Baan IVc4 data for only open transactional data (sales, purchase and production orders), open entries (ACR and ACP), and the sales data related to the Product Configurator (tipcf).

This last point was critical, as Miller Industries is on a rapid deployment schedule and needed to bring over their open items separately to allow operations to continue during the data migration. In addition, the data migration and testing would take less than half the time to accomplish.

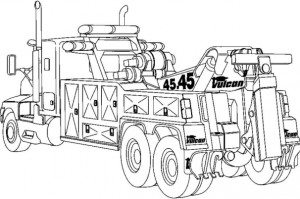

Miller Industries is the World’s Largest Manufacturer of Towing & Recovery Equipment and operates under the well known name brands of Century, Challenger, Holmes, Champion, Eagle, Chevron, Vulcan, Jige, and Boniface.

Miller Industries provides a complete line of quality equipment including: carriers up to 30 feet with deck capacities reaching 30,000 lbs, and towing and recovery units with boom capacities up to 75 tons, all sold and serviced through the largest distribution network in the industry.

Miller Industries, Inc. manufactures vehicle towing and recovery equipment, offering a range of wrecker, car carrier, and trailer bodies.

Miller’s wreckers range from the conventional tow truck to large recovery vehicles of 8 to 70 tons capability, which are used to recover and tow disabled vehicles and other equipment.

The company’s car carriers are flat-bed vehicles with hydraulic tilt mechanisms that enable a towing operator to drive or winch a vehicle onto the bed for transport. Car carriers transport new or disabled vehicles and other equipment, as well as transport vehicles or other equipment over longer distances. Its multi-vehicle transport trailers are auto transport trailers with upper and lower decks and hydraulic ramps for loading vehicles.

The trailers are used for moving multiple vehicles for auto auctions, car dealerships, leasing companies, and other applications. Miller Industries sells its products through independent distributors in the U.S., Canada, and Mexico, as well as in Europe, the Pacific Rim, and the Middle East. The company was founded in 1994 and is based in Ooltewah, Tenn.